Zero-mass interlaminar reinforcement

NAWAH Stitch is the ultimate interlaminar reinforcement for composites.

The NAWAH 3D Nanocarbon is integrated between the composite layers.

NAWAH Stitch reduces drastically delamination

The integration of NAWAH 3D nanocarbon between the fiber layers slows the propagation of microcracks in the thickness of the layers and drastically reduces delamination.

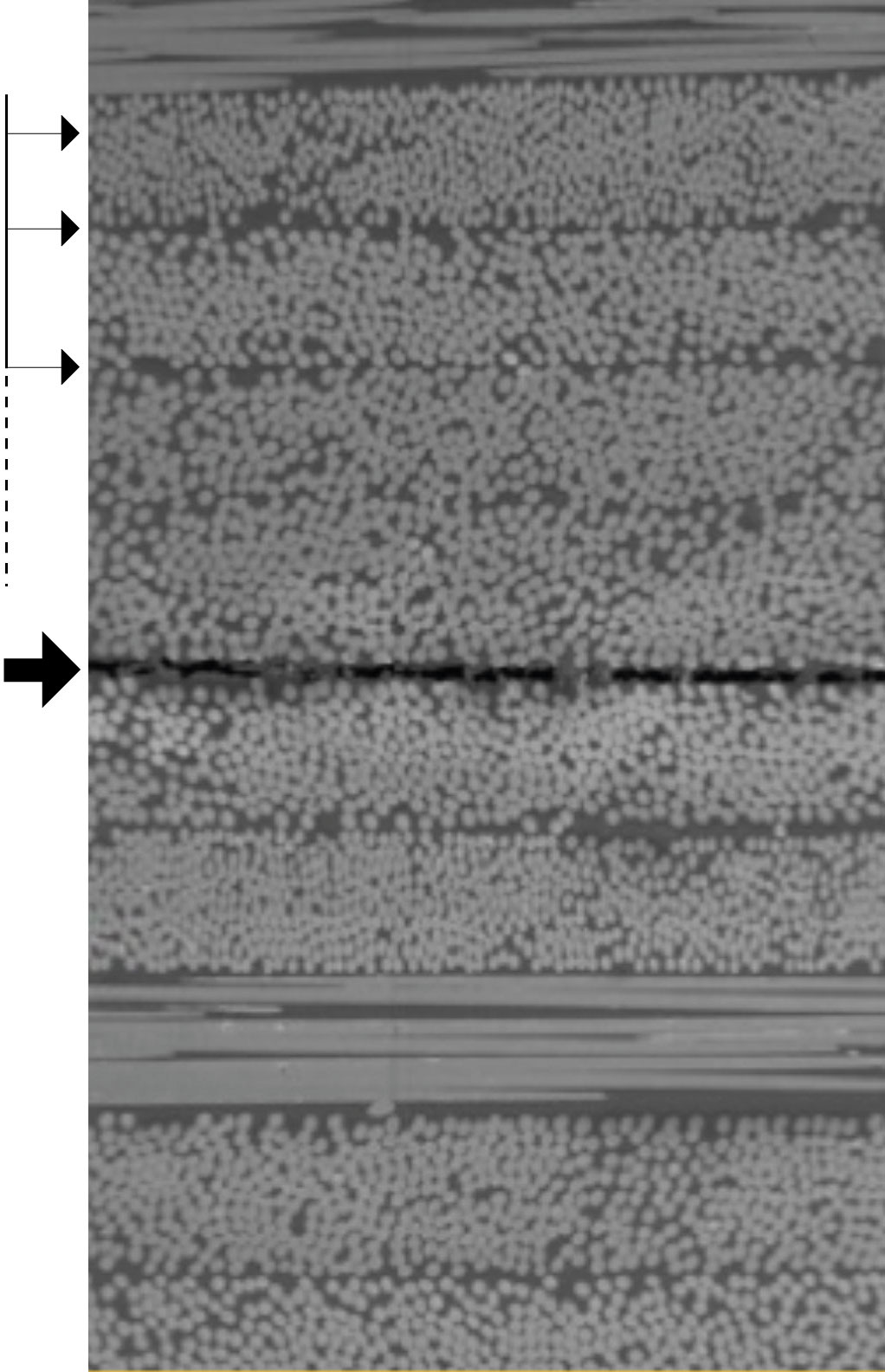

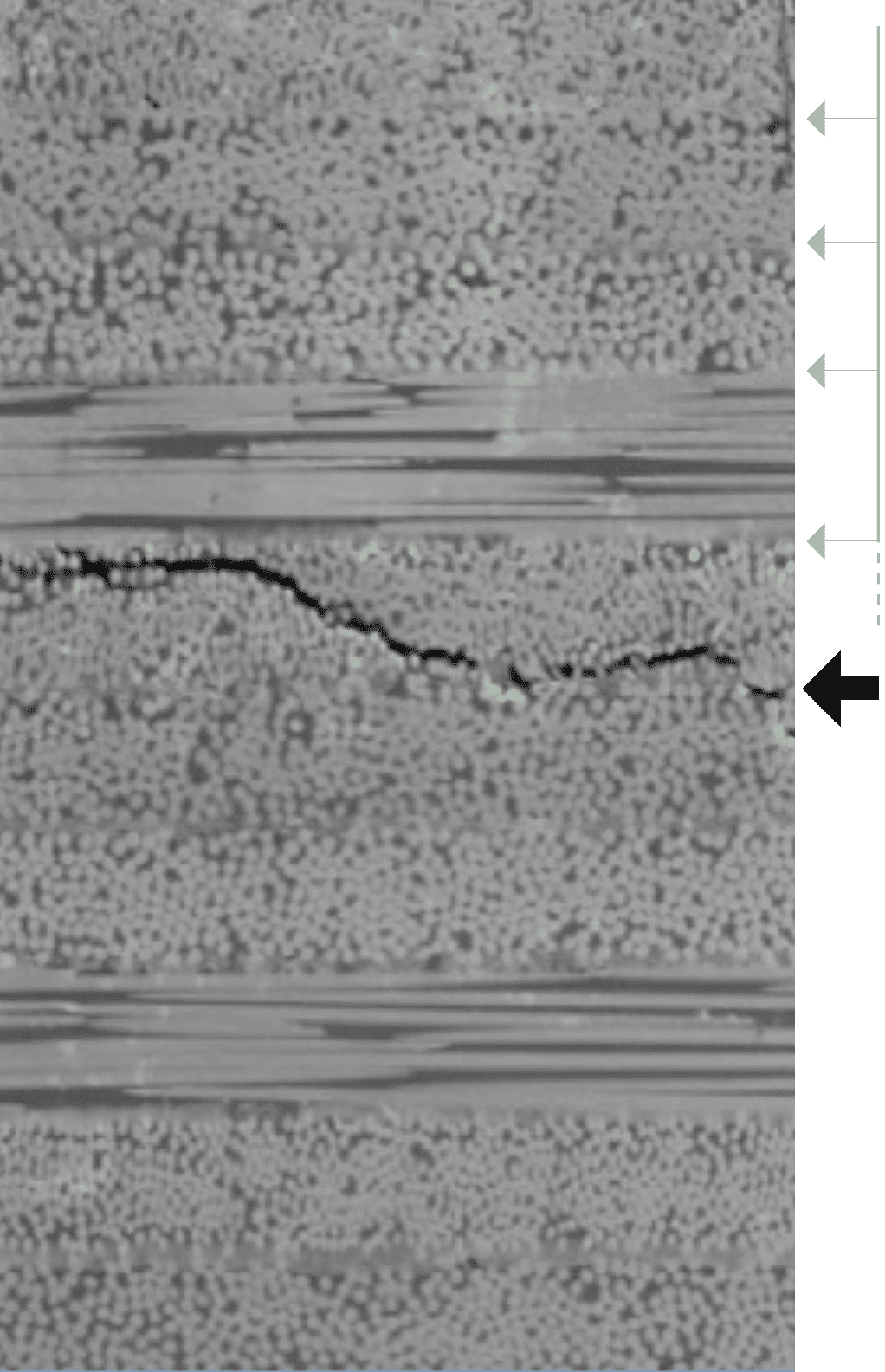

Without NAWAH Stitch

No NAWAH Stitch

at interfaces

Fracture propagates along interface

With NAWAH Stitch

NAWAH Stitch

at interfaces

Fracture is driven into ply and stops propagation

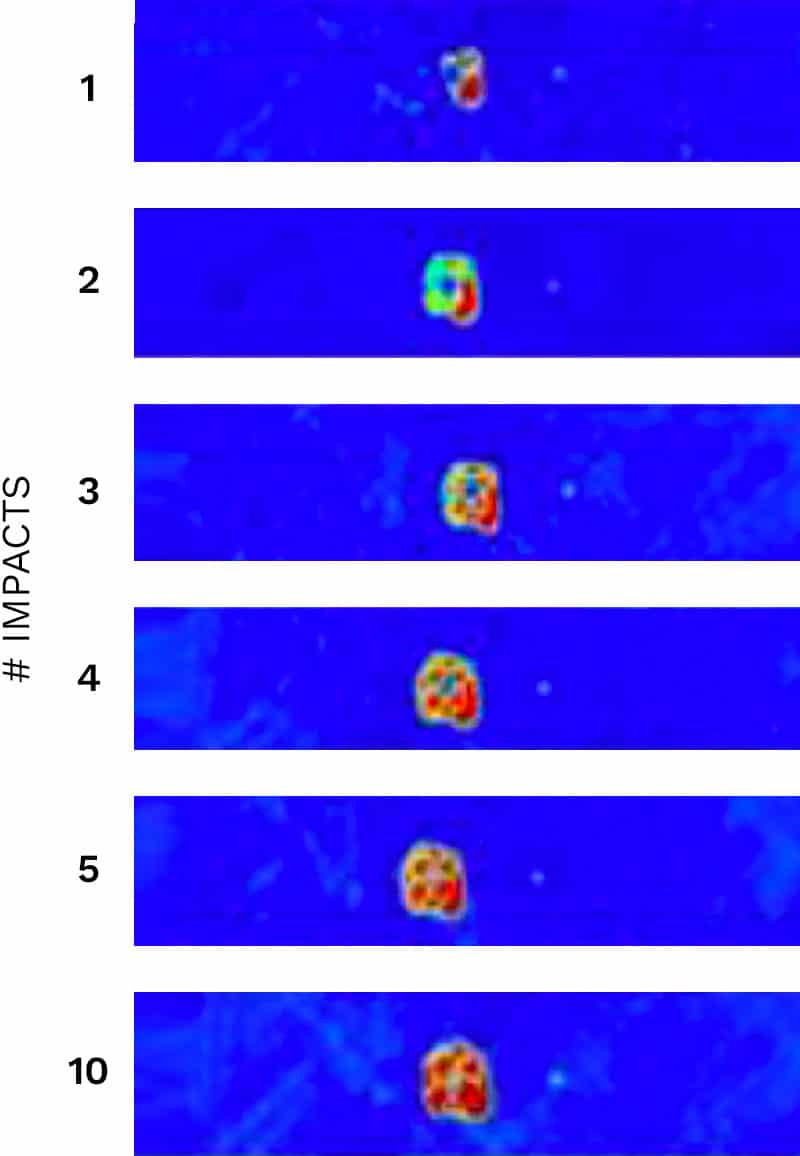

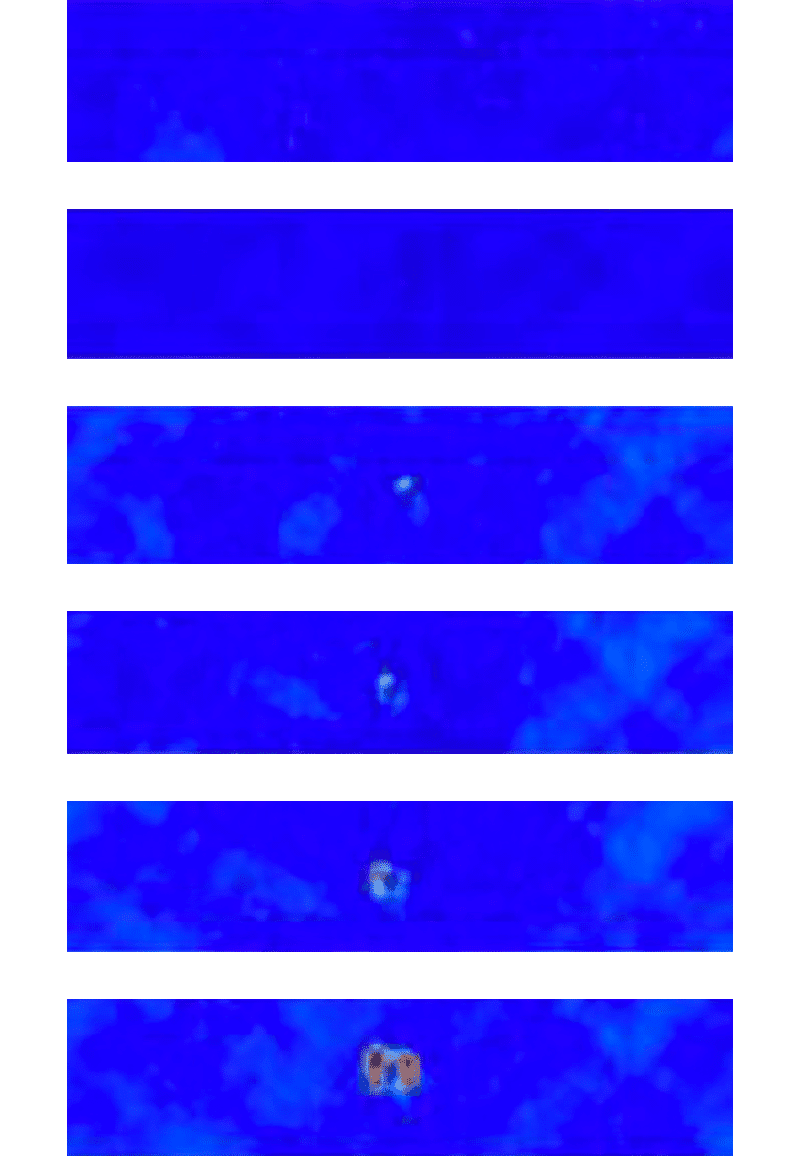

NAWAH Stitch increases resistance to fatigue and repeated impacts

NAWAH Stitch makes it possible to extend the lifespan of the most stressed composite parts or to make possible the use of previously unthinkable composite materials. With a weight of only 2 g/m2, NAWAH Stitch can also make it possible to lighten composite parts with equivalent mechanical performance.

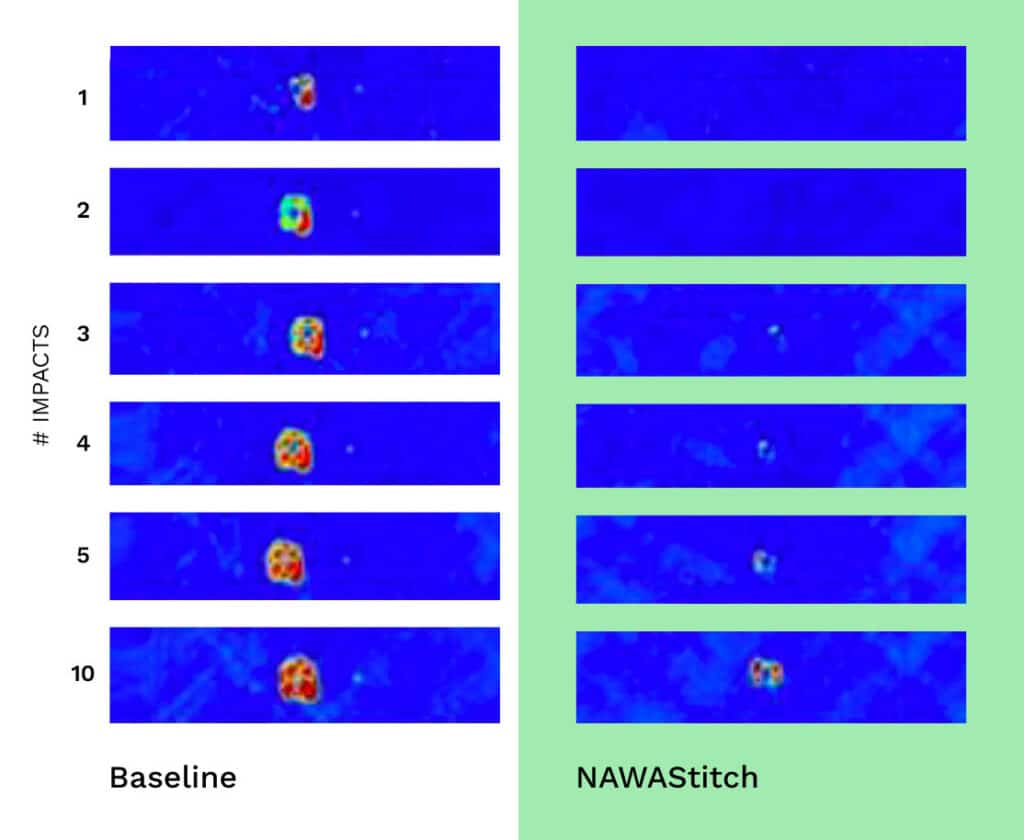

Impact resistance test

Impact damage progression (3.3.J/mm)

Baseline

NAWAH Stitch

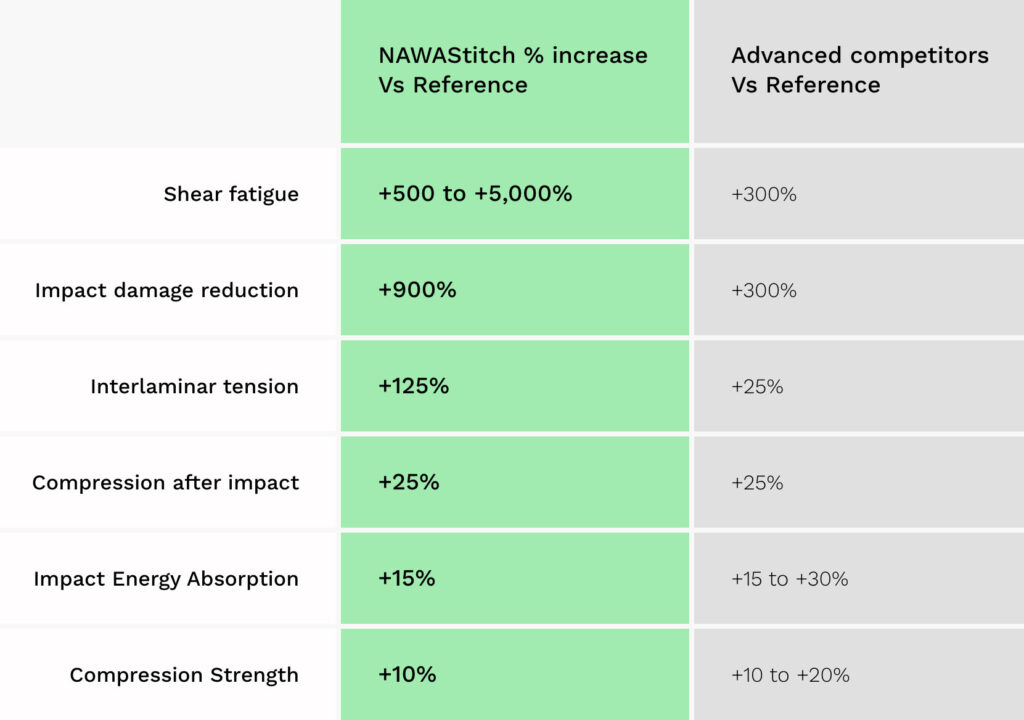

NAWAH Stitch Vs Competition

NAWAH Stitch outperforms market reference and also most advanced reinforcement solution competitors.

NAWAH Stitch % increase

Vs Reference

Advanced competitors

Vs Reference

Shear fatigue

+500 to +5,000%

+300%

Impact damage reduction

+900%

+300%

Interlaminar tension

+125%

+25%

Compression after impact

+25%

+25%

Impact Energy Absorption

+15%

+15 to +30%

Compression Strength

+10%

+10 to +20%

NAWAH Stitch-TS-PPG for thermoset composites

NAWAH Stitch-TS-PPG is a product that can be used directly for the manufacturing of your composite parts, it consists of NAWAH 3D nanocarbon transferred to a reference prepreg (or to the prepreg of your choice) and a protective film.

NAWAH Stitch-TS-PPG is available in rolls of 20 meters in length.

Customers stories

Functionalized composites

The very high electrical and thermal conductivity of NAWAH’s 3D nanocarbon offers the possibility of creating new functions for composite products.

Structural health monitoring

Electrically powered, the composite heats by the Joule effect thanks to NAWAH’s 3D nanocarbon.

A simple thermal camera then makes it possible to quickly check the integrity of the composite product.

De-icing

Electrically powered, the composite heats by the Joule effect thanks to NAWAH’s 3D nanocarbon and melts the frost present.

Client: Santa Cruz Bikes (USA)

Application client: bikes rim for the Mountain Bike World Cup

Product: NAWAH Stitch-TS-PPG

Target objectiv: unbreakable rims

“In downhill racing, the wheels suffer hard, repeated impacts with rocks and roots. Failures occur when the tire bottoms out and the rim bead cracks. NAWAH Stitch has made the wheels much stronger, we believe by increasing the buckling resistance of the inner surface of the rims during these high compressions”

Nic McCrae

Senior composites engineer